Ejector pins play a vital role in manufacturing, especially in die casting and injection molding. These small but powerful components are often overlooked, but they are crucial to ensuring the precision and efficiency of the production process. In this blog, we’ll delve into the importance of knockout pins in industrial manufacturing and highlight their impact on product quality and overall production efficiency.

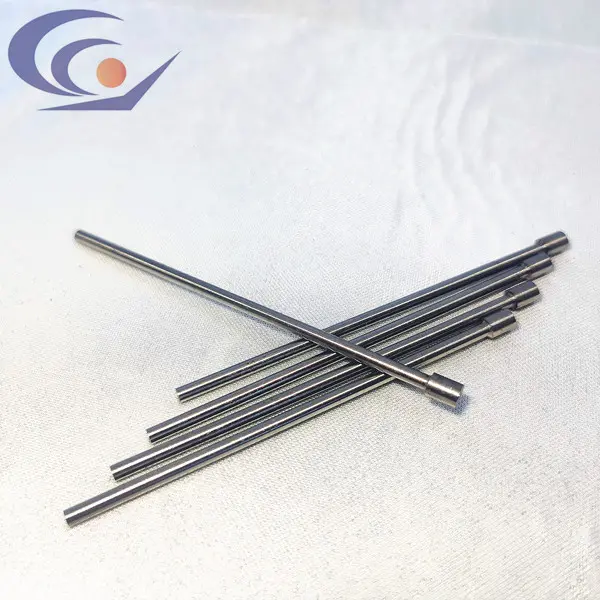

Knock out pins are used in die casting and injection molding to release the final product from the mold. They are designed to withstand high pressures and temperatures, making them an integral part of the manufacturing process. If the knockout pin is not functioning properly, the risk of product defects and production delays increases significantly. Therefore, manufacturers must understand the importance of investing in high-quality ejector pins and maintaining them regularly to ensure optimal performance.

One of the main advantages of using ejector pins is their ability to facilitate smooth ejection of molded products from the mold cavity. This not only ensures the integrity of the final product, but also helps improve the overall efficiency of the manufacturing process. By minimizing the risk of product sticking or deformation, knockout pins play a vital role in maintaining quality standards and reducing the possibility of rework or scrapped parts.

In addition to their role in product ejection, ejector pins also help improve the overall precision and accuracy of the manufacturing process. By providing even pressure and support during ejection, these pins help achieve consistent and reliable manufacturing results. This is especially important in industries where accuracy and consistency are critical, such as automotive and aerospace manufacturing.

In addition, ejection pins are essential to ensure the safety of the production process. By effectively releasing the final product from the mold, they reduce the risk of manual intervention and potential workplace accidents. This not only protects the integrity of the product, but also safeguards the well-being of manufacturing personnel.

It is important for manufacturers to carefully select the ejector pin that is suitable for their specific production requirements. Factors such as material composition, heat resistance and dimensional accuracy should be considered to ensure optimal performance and longevity of these components. Additionally, regular maintenance and inspection of ejector pins is critical to identifying and resolving any potential issues that may arise during the manufacturing process.

In summary, ejector pins are an indispensable component in industrial manufacturing, especially in die casting and injection molding. Their role in facilitating smooth demolding of molded products, ensuring precision and accuracy, and promoting safety cannot be underestimated. Therefore, manufacturers should prioritize the selection and maintenance of high-quality ejector pins to maintain the integrity of their production processes and the quality of their final products. By recognizing the importance of ejection pins, manufacturers can increase overall production efficiency and achieve superior manufacturing results.

Post time: Dec-07-2023