Introduce:

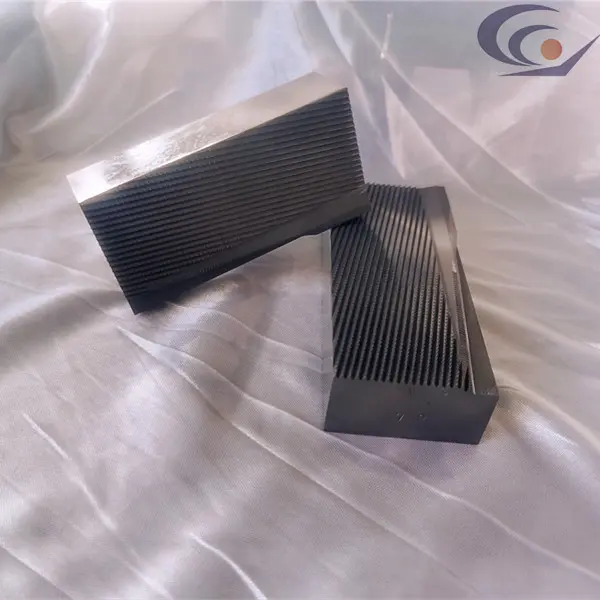

Achieving perfect thread form is an important aspect in various industrial applications such as automotive, aerospace and manufacturing. One way to ensure the precision and accuracy of thread machining is to use a thread rolling cylindrical die. In this blog, we will delve into the concept of thread rolling cylindrical dies, explore their significance, and highlight their contributions to manufacturing.

Understand the process:

Thread rolling cylindrical dies are specially designed tools for forming external or internal threads through the cold forming process. Unlike traditional cutting methods, thread rolling applies pressure to deform the material, producing threads with the highest precision and strength. This cost-effective technology is known for its ability to improve thread quality, control dimensional accuracy and improve the mechanical properties of components.

Advantages of thread rolling cylindrical die:

1. Increased Strength: Thread rolling results in work-hardened threads, resulting in stronger, more durable components. By displacing material rather than removing it, thread rolling significantly improves the fatigue resistance of threads, making it ideal for critical applications.

2. Improved thread quality: The precise design and application of thread rolling cylindrical dies ensures consistent thread geometry and surface finish. This not only enhances the assembly process, but also eliminates the risk of threads coming off or fraying during operation.

3. Increased efficiency: Compared with other forming methods, thread rolling can achieve faster production rates. The ability to roll multiple threads simultaneously reduces machining time and increases overall efficiency, making it the first choice for high-volume production.

Application of thread rolling cylindrical die:

1. Fasteners and bolts: Thread rolling is widely used to produce high strength fasteners and bolts. The hardened threads produced by this process are more resistant to fatigue and vibration, ensuring the integrity and longevity of the end product.

2. Automobile industry: Rolling cylindrical dies play a vital role in the production of various auto parts, such as engine parts, transmission systems, suspension parts, etc. The ability to create precise and strong threads contributes to overall vehicle performance, safety and reliability.

3. Aerospace: The aerospace industry requires extreme precision and reliability for each component. Thread rolling ensures that the thread profiles produced meet strict quality standards, providing secure fastening solutions for critical aircraft structures.

In conclusion:

Thread Rolling Cylindrical Dies have revolutionized the way threads are formed in modern manufacturing. With their ability to create strong, precise and durable threads, they have become the cornerstone of various industries. From improving the efficiency of the production process to ensuring the service life of the product, thread rolling cylindrical dies play an extremely important role in the manufacturing industry. So next time you’re admiring a perfectly threaded part, remember the artistry and precision that thread rolling cylindrical dies bring.

Post time: Aug-24-2023