Carbide Drywall Screw Main Dies

Introduce:

Drywall screws are an important part of the construction industry, ensuring the stability and durability of your structure. Behind the seemingly simple design lies the involvement of various manufacturing processes and materials. One of the key components is the carbide main dies, an indispensable tool that plays an important role in the production of high-quality drywall screws. In this blog post, we’ll delve into the importance of molding and shed light on its significant contribution to the drywall screw manufacturing process.

The role of the main die in drywall screw production:

Drywall screws are formed through a thread rolling process in which cylindrical pieces of metal are transformed into screws with precisely spaced threads. In this case, the mold refers to the specialized tool that creates these threads. Its main function is to press the screw blank to form the required thread shape.

Understand the carbide main dies:

The choice of mold material is crucial because it directly affects the quality and performance of the screw. Known for its excellent hardness and wear resistance, cemented carbide is the material of choice for manufacturing master molds. By combining carbide with tungsten, a highly durable and heat-resistant tool can be created, ensuring longevity and reliability during the thread rolling process.

PRODUCT DESCRIPTION

Carbide die is a conventional die for screw heading machine.It is made of tungsten materials with high strength and hardness, corrosion resistance, wear resistance and high temperature resistance.It is used for producing screw head and body parts.Also named Tungsten dies.

Mian product of carbide die: main die,first punch,cutter die, cutter knife,first punch case,second punch case,and other carbide dies.

All carbide die for drywall screw,chipboard screw, self-drill screw,tappingscrew,

wooden screw.

If you order the carbide die, please let me know the machine type,moulds diameter, length,wire diameter,and screw drawing or mould drawing .

We can produced the accroding to your drawing and we can R&D accroding to your samples and customer's request.

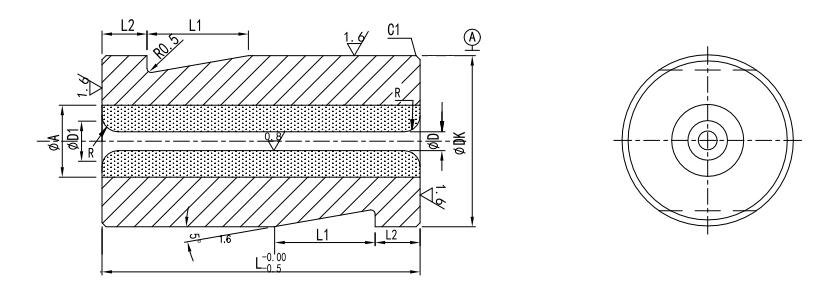

TECHNICAL SPECIFICATION

L:Mian die length and tengsten length L1&L2: Position slot

DK:Mian die diameter

A:Tungsten diameter R:radians

D: Mian die hole or wire diameter D1:Screw head diameter

MATERIAL

HSS+TUNGSTEN

We will accroding to your machine, products,material,choosing good material, hardness and manufacturing technique.We will provide you with the best solution.

ADVANTAGE

Our carbide die will first check the quality in my testing factory or our friendship factory.

When you get the dies, if you have any problems, we will send you best service via Video or On line.

We can make Form A, Form E, CO.

DELIVERY TIME

Standard Size:15 Working days

Customization:15-20Working days

MOQ

Standard Size: 2Pcs.

Customization: 2Pcs

PACKING

Packed with antishock material.

QC FOR CARBIDE DIE

We are equipped with Rockwell hardness tester, Inlaying machine, Micrometer,

Microscope,3-D inspection instruments and other testing equipment, to ensured the good quality of carbide die.

SAMPLES

We can offer 1-2Pcs as samples to check the size and testing quality, but you should pay the cost and shipping cost.

PAYMENT METHOD:

Advance TT, T/T, Western Union, Paypal.

TRANSPORT DETAILS

Shipment by Air, by Train, by Sea, by TNT, DHL,SF-express.

APPLICATIONS

Drywall screw,Chipboard screw, Self-drill screw,Tapping screw,Wooden screw,Machine screw,Furniture screw,Electronic screw,Combination screw,Blot,Nuts and other screws.

EXPORT MARKETS

Thailand,Vietnam,Indonesia,Malaysia,India,Turkey,Iran,Russia,Pakistan,Uzbekistan,Kazakhstan, and more countries or regions.

Advantages of cemented carbide tungsten main die:

1. Longer service life:

Carbide is incredibly hard, making the master mold extremely wear-resistant. As a result, they maintain their shape and performance over a longer period of time, reducing the need for frequent replacements and ensuring continuous production without interruption.

2. Enhance thread quality:

The high precision achieved by the carbide master tool plays an important role in producing screws with precise thread profiles. This results in screws that exhibit higher retention, reduced propensity for delamination, and enhanced overall performance.

3. Best heat resistance:

The carbide tungsten main die has excellent thermal stability and can withstand the high temperatures generated during the thread rolling process. This feature ensures that the mold remains in optimal condition, maintaining consistent thread quality even during long production runs.

4. Cost-effective solution:

The upfront cost of investing in a carbide tungsten main die can be higher compared to other options. However, their exceptional durability and low maintenance requirements can result in long-term cost savings as they need to be replaced less frequently, significantly reducing downtime and associated expenses.

In conclusion:

Carbide tungsten main dies have become an important tool in the production of high-quality drywall screws. Its exceptional hardness, wear resistance and thermal stability make it an ideal material for creating consistent and precise thread profiles. Understanding the critical role of the master mold allows manufacturers to optimize the production process and ensure the production of reliable and durable screws. By investing in carbide tungsten main dies, manufacturers can benefit from improved screw quality, extended mold life, increased production efficiency, and ultimately satisfied customers.