Advantages Of Convex Head Carbide Main Dies In Industrial Applications

PRODUCT DESCRIPTION

Carbide die is a conventional die for screw heading machine.It is made of tungsten materials with high strength and hardness, corrosion resistance, wear resistance and high temperature resistance.It is used for producing screw head and body parts.Also named Tungsten dies.

All carbide die for drywall screw,chipboard screw, self-drill screw,tappingscrew,

wooden screw.

If you order the carbide die, please let me know the machine type,moulds diameter, length,wire diameter,and screw drawing or mould drawing .

We can produced the accroding to your drawing and we can R&D accroding to your samples and customer's request.

TECHNICAL SPECIFICATION

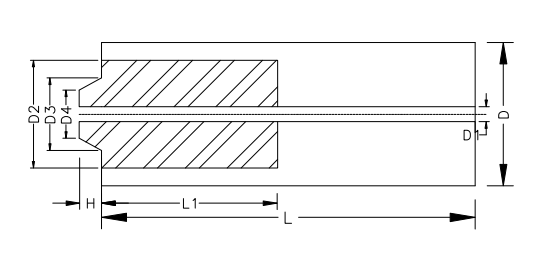

L:Mian die length L1: tengsten length

D:Mian die diameter D1: Mian die hole or wire diameter

D2:Tungsten diameter D3&D4:Screw head diameter

H: Head height

MATERIAL

HSS+TUNGSTEN

We will accroding to your machine, products,material,choosing good material, hardness and manufacturing technique.We will provide you with the best solution.

ADVANTAGE

Our carbide die will first check the quality in my testing factory or our friendship factory.

When you get the dies, if you have any problems, we will send you best service via Video or On line.

We can make Form A, Form E, CO.

DELIVERY TIME

Standard Size:15 Working days

Customization:15-20Working days

MOQ

Standard Size: 2Pcs.

Customization: 2Pcs

PACKING

Packed with antishock material.

QC FOR CARBIDE DIE

We are equipped with Rockwell hardness tester, Inlaying machine, Micrometer,

Microscope,3-D inspection instruments and other testing equipment, to ensured the good quality of carbide die.

SAMPLES

We can offer 1-2Pcs as samples to check the size and testing quality, but you should pay the cost and shipping cost.

PAYMENT METHOD:

Advance TT, T/T, Western Union, Paypal.

TRANSPORT DETAILS

Shipment by Air, by Train, by Sea, by TNT, DHL,SF-express.

APPLICATIONS

Drywall screw,Chipboard screw, Self-drill screw,Tapping screw,Wooden screw,Machine screw,Furniture screw,Electronic screw,Combination screw,Blot,Nuts and other screws.

EXPORT MARKETS

Thailand,Vietnam,Indonesia,Malaysia,India,Turkey,Iran,Russia,Pakistan,Uzbekistan,Kazakhstan, and more countries or regions.

Introduce

In the field of industrial manufacturing, precision and durability are fundamental aspects that can significantly affect production efficiency and product quality. The main mold is one of the important components that plays a vital role in the material molding process. It requires extremely high precision and elasticity. This blog explores the benefits of using raised carbide master tools, highlighting their superior properties and their impact on industrial applications.

1. Understand the convex carbide master mold

Convex head carbide main dies are advanced tools widely used in industrial environments due to their exceptional durability and precision. These molds feature specially designed heads made of carbide, a high-performance material known for its exceptional strength and wear resistance. The master mold is the main component responsible for material shaping during the manufacturing process. The unique design of the convex carbide master mold improves its efficiency.

2. Enhance durability and wear resistance

One of the unique advantages of using a convex head carbide main die is its exceptional durability and wear resistance. Carbide is known for its hardness and wear resistance, making it ideal for applications involving heavy-duty operations. Compared with traditional steel master molds, convex head carbide main dies have a significantly longer service life and reduced maintenance requirements, ultimately delivering cost benefits to industrial manufacturing companies.

3.Excellent precision and surface finish

Precision is critical in manufacturing, and convex head carbide main dies provide unparalleled precision. The tapered shape of the nose ensures consistent pressure distribution during the molding process, resulting in a uniform and precise product shape. Additionally, the smooth surface finish achieved by these molds eliminates the need for additional processes, saving time and resources.

4.Material molding versatility

Protruding carbide master molds offer exceptional versatility in forming materials, making them suitable for a wide range of industrial applications. From plastic injection molding to sheet metal forming, these molds can accurately and efficiently shape a variety of materials. Their flexibility allows manufacturers to streamline production processes and achieve consistent results across multiple materials, reducing the need for additional investment in specialized tooling.

5. Improve efficiency and productivity

By incorporating male carbide master molds into industrial applications, companies can witness significant improvements in efficiency and productivity. Superior durability, precision and versatility combine to increase production speed and reduce downtime, resulting in higher output and profitability. Additionally, the reduced need for mold replacement and maintenance further improves overall productivity and reduces costs in the long run.

In conclusion

Projected carbide master molds are changing manufacturing by delivering superior durability, precision and versatility. The use of these advanced tools enables industrial manufacturers to take their production processes to new heights, ensuring consistent quality and increasing efficiency. As the industry continues to evolve, integrating male carbide master molds into manufacturing operations has become critical for those seeking to remain competitive in the global marketplace.